Introduction: Unveiling the Unsung Hero of Plumbing

When building or renovating a property, we often focus on visible elements like walls, fixtures, and flooring. However, an essential component goes unnoticed but plays a vital role in maintaining a clean and functional space – the floor drain. Floor drains are the unsung heroes of plumbing systems, responsible for effectively draining water and preventing flooding in areas such as bathrooms, kitchens, and basements. This comprehensive guide will delve into the world of floor drains, covering everything from their importance and types to installation and maintenance tips.

Why Are Floor Drains Essential?

Floor drains serve as a first line of defense against water damage and potential hazards. They prevent water accumulation, safeguarding your property against flooding, mold, and mildew. Floor drains, such as bathrooms and utility rooms, are crucial in moisture-prone areas. By efficiently channeling water away, floor drains help maintain a clean, dry, and safe environment.

Types of Floor Drains: Choosing the Right One for Your Needs

Floor drains come in various types and designs to suit different applications. Understanding the options available can help you decide on your specific requirements.

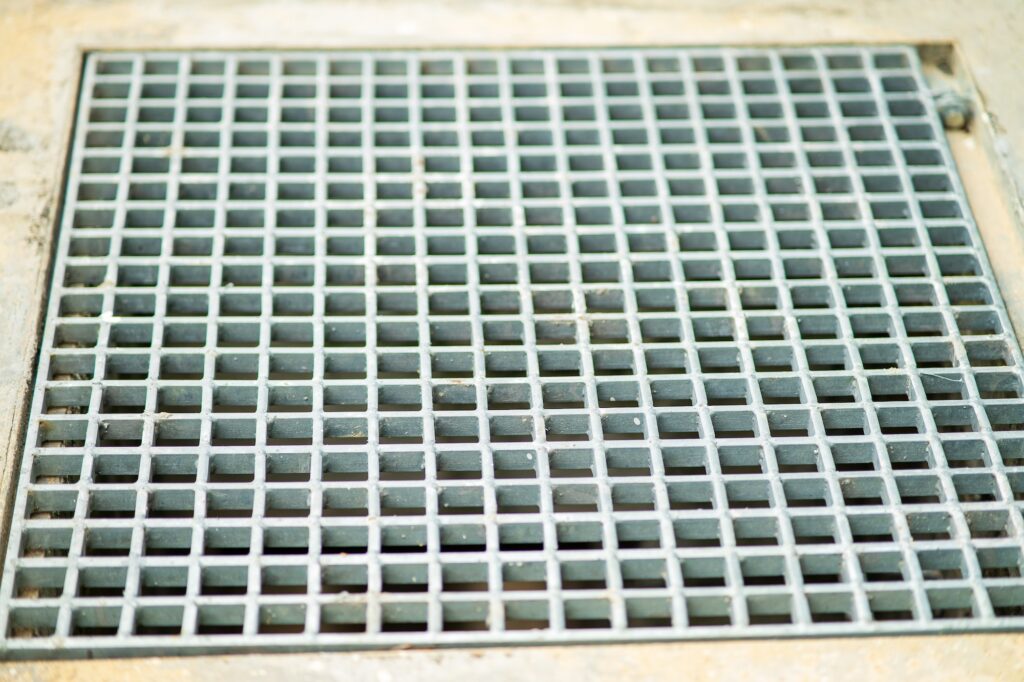

- Traditional Floor Drains: These are the most common type of floor drains and feature a square or round shape with a removable grate. They are versatile and widely used in residential, commercial, and industrial settings.

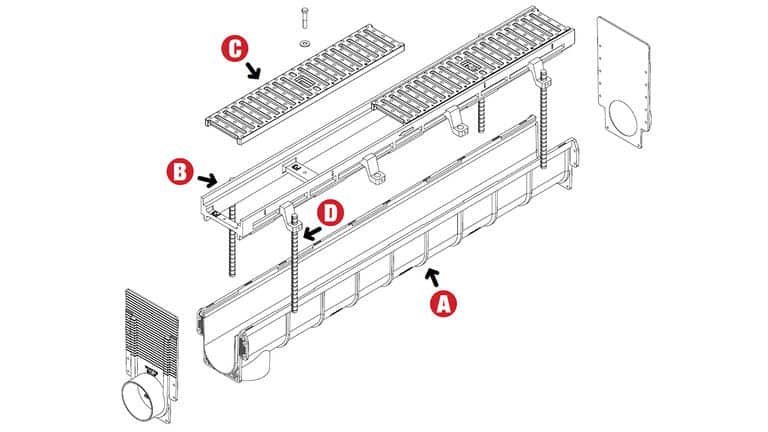

- Trench Drains: Trench drains, also known as linear drains, are long and narrow channels with a continuous grate. They are ideal for areas that require a larger drainage capacity, such as driveways, swimming pools, and commercial kitchens.

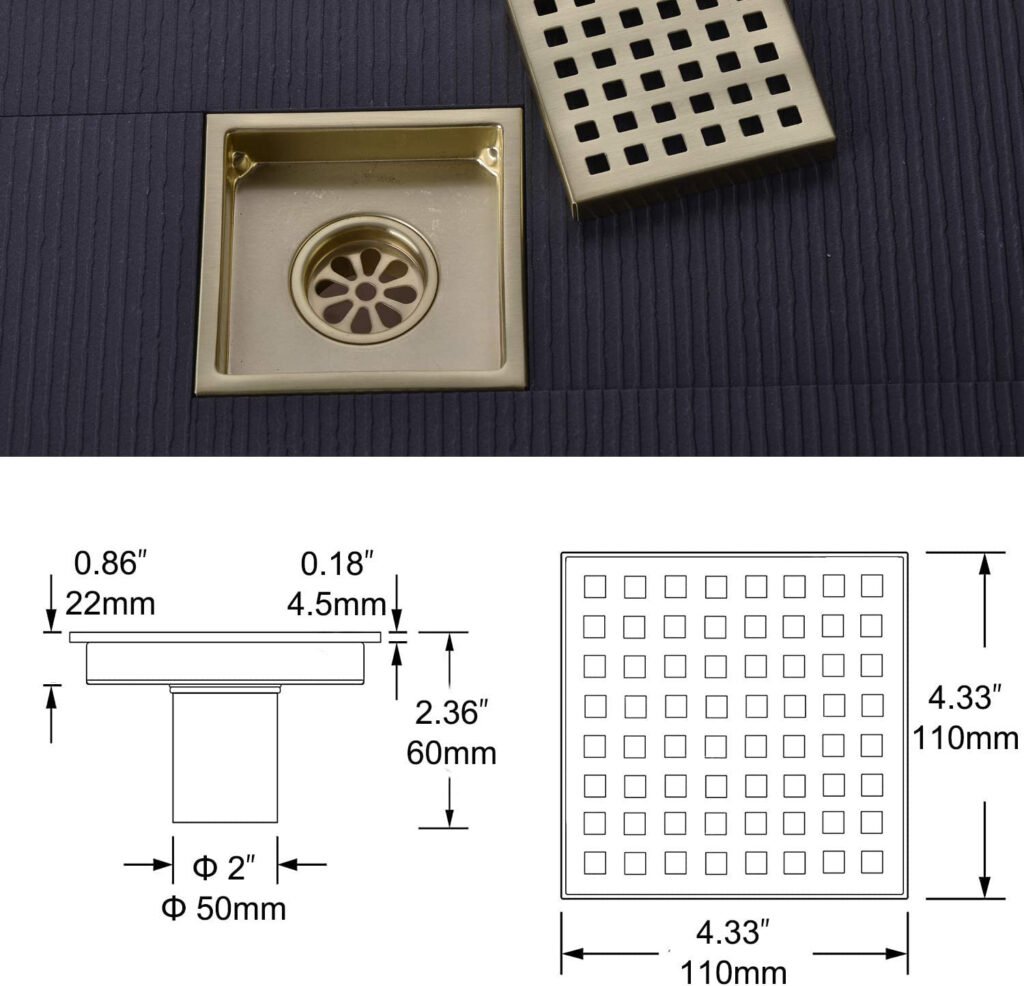

- Point Drains: As the name suggests, point drains are single-point drains that typically have a small circular or square opening. They are commonly used in showers, where water is concentrated in one area.

Invest in a Reliable Floor Drain System

A well-designed and properly installed floor drain system is crucial to any property. It provides peace of mind by efficiently managing water flow, preventing flooding, and maintaining a clean and safe environment. Whether you opt for a traditional floor drain, trench drain, or point drain, ensure you invest in a high-quality product from a reputable manufacturer like HOFEN Drain. HOFEN Drain aims to exceed customer expectations and establish long-lasting partnerships by prioritizing personalized service, product quality, and timely delivery. So, don’t overlook the importance of a reliable floor drain system when designing or renovating your space.

Applications

Floor drains have a wide range of applications across various industries and settings. Understanding the specific needs of your project can help you select the right floor drain for optimal performance. Here are some common applications where floor drains are essential:

Residential Spaces: Floor drains play a crucial role in residential areas, especially in bathrooms, laundry rooms, and basements. They prevent water damage and maintain a clean and safe environment.

Commercial Buildings: Restaurants, hotels, shopping malls, and other commercial spaces rely on floor drains to manage water flow in kitchens, restrooms, and common areas.

Industrial Facilities: Industrial settings such as manufacturing plants, warehouses, and factories often require heavy-duty floor drains to handle large volumes of water, chemicals, and debris.

Outdoor Environments: Driveways, parking lots, and outdoor recreational areas benefit from trench drains that effectively channel rainwater and prevent flooding.

Raw Materials

The choice of raw materials for floor drains depends on durability, corrosion resistance, and aesthetic appeal. Here are some commonly used materials for floor drains:

Stainless Steel: Stainless steel is popular due to its excellent corrosion resistance, durability, and aesthetic appeal. It is suitable for a wide range of applications, including both residential and commercial spaces.

Brass: Brass floor drains offer durability, strength, and corrosion resistance. They are often used in commercial and industrial settings requiring heavy-duty performance.

PVC: PVC (polyvinyl chloride) is a lightweight, cost-effective option for floor drains. It is commonly used in residential applications and areas with lower water flow requirements.

Sizes

Floor drains are available in various sizes to accommodate water flow rates and installation requirements. The size of a floor drain is typically determined by its outlet diameter. Here are some standard sizes for floor drains:

Two inches (50 mm): This size is commonly used for residential applications, including showers, utility rooms, and small bathrooms.

3 inches (75 mm): Suitable for larger residential spaces, commercial kitchens, and light industrial environments where moderate water flow is expected.

4 inches (100 mm): This size is ideal for heavy-duty commercial and industrial applications that require high water flow capacity.

Remember, it is essential to consult with professionals or manufacturers to determine the appropriate size of floor drain based on your specific project requirements.

Customization: Tailoring Your Floor Drain System

Floor drains can be customized to meet the unique needs of your project. Customization options include:

- Design: Choose from various grate styles, shapes, and patterns to complement your aesthetic preferences and architectural design.

- Accessories: Enhance the functionality of your floor drain system by adding accessories such as sediment buckets, removable grates, and water traps.

- Special Requirements: Discuss any special requirements with the manufacturer, such as ADA compliance, specific load-bearing capacities, or unique installation needs.

By working closely with a reputable manufacturer like HOFEN Drain, you can customize your floor drain system to ensure optimal performance and meet the specific demands of your project.

Designing a Floor Drain System to Fit Your Needs

When selecting a floor drain system, consider the applications, raw materials, and sizes that align with your project requirements. Choosing the right floor drain for residential, commercial, or industrial use ensures efficient water management and protects against water damage. Remember to collaborate with a trusted manufacturer like HOFEN Drain to customize your floor drain system, guaranteeing its functionality, durability, and seamless integration within your space.

Bronze Floor Drains and Nickel Bronze Floor Drains: Aesthetic Appeal and Durability

Bronze Floor Drains

Bronze floor drains are famous for those seeking a classic and timeless aesthetic. Bronze, an alloy primarily composed of copper and tin, offers several benefits for floor drain applications. Here are some key features and advantages of bronze floor drains:

Aesthetic Appeal: Bronze has a warm, rich color that adds elegance and sophistication to any space. It blends well with traditional, rustic, or vintage design themes, making it a favored choice for residential and commercial settings where aesthetics are important.

Corrosion Resistance: Bronze exhibits excellent corrosion resistance, making it suitable for humid or moisture-prone areas such as bathrooms and kitchens. Its resistance to rust and degradation ensures long-lasting performance and durability.

Strength and Durability: Bronze is a robust material that withstands heavy loads and foot traffic. It is known for its high tensile strength and resistance to wear and tear, ensuring a reliable and sturdy floor drain system.

Low Maintenance: Bronze floor drains are relatively low maintenance. They require periodic cleaning to remove debris and ensure optimal water flow. Routine cleaning helps maintain their shine and extends their lifespan.

Nickel Bronze Floor Drains

Nickel bronze is a variant of bronze that contains added nickel, further enhancing its properties and performance. Nickel bronze floor drains offer additional advantages, making them a preferred choice for certain applications. Here are the key features and benefits of nickel bronze floor drains:

Enhanced Corrosion Resistance: Adding nickel to the alloy enhances the corrosion resistance of nickel-bronze floor drains. This makes them particularly suitable for harsher environments, such as coastal areas with high salt content in the air or spaces exposed to chemicals.

Higher Strength: Nickel bronze exhibits greater strength and hardness compared to traditional bronze, making it an excellent choice for heavy-duty applications. It can withstand higher loads and pressures, ensuring long-term durability and reliability.

Versatility: Nickel bronze floor drains are available in various designs and finishes, allowing customization to match different design preferences and architectural styles. They provide versatility while still maintaining the aesthetic appeal associated with bronze.

Choosing Between Bronze and Nickel Bronze Floor Drains

Choosing between bronze and nickel bronze floor drains ultimately depends on your needs, aesthetic preferences, and environmental factors. Bronze floor drains are an excellent choice if you prioritize a classic look and require corrosion resistance. On the other hand, nickel-bronze floor drains are a suitable option if you need enhanced corrosion resistance and higher strength.

To ensure you make the right decision, consult with a trusted manufacturer like HOFEN Drain. They can provide guidance on the best material and finish for your floor drain system, considering your project requirements and desired aesthetic appeal.

Combining Beauty and Durability

Bronze and nickel bronze floor drains offer both aesthetic appeal and durability for a wide range of applications. Whether you choose the timeless charm of bronze or the enhanced corrosion resistance of nickel bronze, these materials provide reliable and long-lasting solutions for your floor drain needs. Collaborate with a reputable manufacturer like HOFEN Drain to explore the options and select the ideal floor drain system that combines beauty and durability for your space.

Stainless Steel Floor Drains vs. Brass Floor Drains:

Stainless Steel Floor Drains

Stainless steel floor drains are popular for their exceptional strength, durability, and corrosion resistance. Here are some key features and advantages of stainless steel floor drains:

Strength and Durability: Stainless steel is known for its high strength and resilience, making it ideal for heavy-duty applications. It can withstand heavy loads and constant foot traffic without compromising its structural integrity.

Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for various environments, including areas with high moisture or chemical exposure. It can withstand harsh substances and resist rust, ensuring a long lifespan and reliable performance.

Low Maintenance: Stainless steel floor drains are relatively low maintenance. They are easy to clean and require minimal upkeep to maintain appearance and functionality. Routine cleaning helps prevent debris buildup and ensures optimal water flow.

Aesthetic Appeal: Stainless steel floor drains have a sleek and modern appearance, making them a versatile choice that complements a range of design styles. Their clean and polished look adds a touch of elegance to both residential and commercial spaces.

Brass Floor Drains

Brass floor drains, made from an alloy of copper and zinc, offer a unique set of characteristics that make them a preferred choice in specific applications. Consider the following advantages of brass floor drains:

Aesthetic Appeal: Brass has a warm and inviting golden hue that adds a touch of elegance and sophistication to any space. It blends well with traditional, vintage, or rustic design themes, making it a popular choice for residential and commercial settings where aesthetics are important.

Corrosion Resistance: Brass is inherently corrosion-resistant, making it suitable for high humidity or moisture environments, such as bathrooms and kitchens. Its corrosion resistance ensures long-lasting performance and minimal degradation over time.

Antimicrobial Properties: Brass has natural antimicrobial properties that help inhibit the growth of bacteria, making it a hygienic choice for areas where cleanliness is crucial, such as healthcare facilities or food preparation areas.

Ease of Machining: Brass is a malleable material, allowing for intricate and detailed designs. This makes it easier to produce decorative or customized floor drain grates that add a touch of elegance to the overall design.

Choosing Between Stainless Steel and Brass Floor Drains

When deciding between stainless steel and brass floor drains, consider the specific requirements of your project and the desired aesthetic appeal. Stainless steel floor drains are well-suited for heavy-duty applications and environments with high moisture or chemical exposure. Brass floor drains, on the other hand, offer a unique and elegant look and inherent antimicrobial properties.

It’s essential to consult with a reputable manufacturer like HOFEN Drain to assess your needs and receive guidance on the best material choice for your floor drain system. They can help you select the most suitable option based on your project requirements, ensuring a durable and visually appealing solution.

Balancing Strength and Aesthetics

Both stainless steel and brass floor drains offer distinct advantages depending on your project requirements. Stainless steel provides exceptional strength, durability, and corrosion resistance, while brass offers an elegant appearance and natural antimicrobial properties. By collaborating with a trusted manufacturer like HOFEN Drain, you can find the perfect balance between strength, functionality, and aesthetics for your floor drain system.

How to Check the Quality of Floor Drains: A Step-by-Step Guide

Purchasing high-quality floor drains is essential to ensure their longevity, performance, and reliability. Here is a step-by-step guide on how to check the quality of floor drains before making a purchase:

1. Research and Choose Reputable Manufacturers: Research and select reputable manufacturers known for producing reliable and high-quality floor drains. Look for manufacturers with a track record of delivering durable products and positive customer reviews.

2. Assess Material Quality: Examine the material used to construct the floor drain. If it’s stainless steel, check for the grade and ensure it meets industry standards. For brass floor drains, ensure the brass used is of high quality and free from impurities.

3. Inspect the Construction: Carefully inspect the construction of the floor drain. Check for sturdy and solid construction, ensuring no visible defects or loose components. Pay attention to welds, joints, and connections to ensure they are well-made and secure.

4. Check Grate Strength: The grate of a floor drain should be strong enough to withstand regular foot traffic and potential loads. Gently apply pressure to the grate to ensure it doesn’t bend or flex easily. It should feel sturdy and capable of supporting weight without any weakness.

5. Verify Drainage Efficiency: Assess drainage efficiency by pouring water into the drain or simulating a water flow scenario. Observe how quickly the water drains and if there are any signs of blockages or slow drainage. A high-quality floor drain should facilitate efficient water flow without clogging.

6. Consider Corrosion Resistance: If the floor drain is made of stainless steel or brass materials, ensure it exhibits excellent corrosion resistance. Check for any signs of rust, discoloration, or degradation, indicating poor quality or insufficient corrosion resistance.

7. Evaluate Quality Certifications: Look for any industry certifications or standards the floor drain and its manufacturer comply with. Certifications such as ISO 9001 ensure the manufacturer follows established quality management systems.

8. Seek Warranty and After-Sales Support: Inquire about the warranty provided by the manufacturer. A reliable manufacturer should stand behind their product with a reasonable warranty period. Additionally, consider the availability of after-sales support, including technical assistance or replacement parts if needed.

9. Consult Experts or Professionals: If you’re unsure about assessing the quality of floor drains, don’t hesitate to consult experts or professionals in the plumbing industry. They can provide valuable insights and guidance to help you make an informed decision.

By following these steps and conducting thorough quality checks, you can ensure that the floor drains you purchase meet the highest quality, durability, and performance standards. Collaborating with a reputable manufacturer like HOFEN Drain can also provide peace of mind, as they prioritize product quality and customer satisfaction.

Installation and Replacement of Floor Drains: A Comprehensive Guide

Proper installation and timely replacement of floor drains are crucial for their efficient performance and longevity. Whether you’re installing new floor drains or replacing existing ones, follow this comprehensive guide for a successful installation or replacement process:

1. Plan and Prepare:

Assess the specific requirements of the installation or replacement project. Consider factors such as the location, purpose, and anticipated water flow to determine the appropriate type and size of the floor drain.

Ensure you have all the necessary tools and materials for the installation or replacement, including the floor drain unit, appropriate fittings, sealants, and any required plumbing accessories.

2. Clear the Work Area:

Before beginning the installation or replacement, ensure the work area is clean, clear, and free from obstructions or debris. This allows for easy access and a smooth installation process.

3. Installation Process:

If installing new floor drains, start by marking the desired location on the floor based on plumbing layout and drainage requirements.

Cut an appropriate-sized opening in the floor using a saw or drill, following the manufacturer’s instructions and local building codes.

Connect the floor drain to the plumbing system using the necessary fittings and connectors. Ensure a secure and watertight connection.

Apply an appropriate sealant or plumber’s putty to create a tight seal between the floor drain and the surface, preventing water leakage.

Install the grate securely onto the drain body, ensuring it fits flush and locks in place.

4. Testing and Inspection:

After installation, conduct thorough testing and inspection to ensure the floor drain functions correctly. Pour water into the drain and observe the flow and drainage performance. Check for any leaks or drainage issues that need to be addressed.

5. Replacement Process:

If replacing an existing floor drain, start by turning off the water supply and disconnecting the drain from the plumbing system using the appropriate tools.

Remove the old floor drain carefully, ensuring no damage to the surrounding flooring or plumbing connections.

Clean the area thoroughly, removing any debris or residue left behind by the previous drain.

Follow the abovementioned process for installing the new floor drain in the existing location.

Conduct testing and inspection, as mentioned earlier, to verify the proper functioning of the new floor drain.

6. Seek Professional Assistance if Needed:

If you’re unsure about any aspect of the installation or replacement process or if it involves complex plumbing work, it’s recommended to seek professional assistance from a licensed plumber. They have the expertise and experience to ensure a successful installation or replacement.

Proper installation and regular maintenance are essential to maximize the efficiency and lifespan of your floor drains. By following this guide and collaborating with trusted professionals like HOFEN Drain, you can ensure a seamless installation or replacement process and enjoy the benefits of a reliable and functional floor drain system.

Top 10 FAQs About Floor Drains: Answers to Your Questions

Here are the answers to the top 10 frequently asked questions about floor drains:

1. What is a floor drain?

A floor drain is a plumbing fixture installed to remove water and prevent flooding in areas prone to moisture, such as bathrooms, kitchens, basements, and utility rooms. It consists of a drain body, a grate or cover, and a trap to prevent odors.

2. What are the benefits of using floor drains?

Floor drains offer several benefits, including preventing water damage, maintaining a clean and safe environment, preventing mold and mildew growth, and ensuring efficient wastewater drainage.

3. Are floor drains only used in residential settings?

No, floor drains are used in various residential, commercial, and industrial settings. They are essential in restaurants, hotels, hospitals, manufacturing facilities, and outdoor areas like parking lots and pool decks.

4. How do I choose the right size of floor drain?

The size of a floor drain depends on factors such as the expected water flow rate and the plumbing system’s capacity. Consult a professional plumber or follow local building codes to determine the appropriate size for your application.

5. Can floor drains get clogged?

Yes, floor drains can become clogged over time due to the accumulation of debris, dirt, hair, and other materials. Regular cleaning and maintenance are necessary to prevent clogs and ensure proper drainage.

6. How often should I clean my floor drains?

Cleaning frequency depends on factors like usage, location, and the presence of debris. It is generally recommended to clean floor drains at least once every few months. However, areas with high usage or heavy debris may require more frequent cleaning.

7. Can floor drains be customized to match my design preferences?

Yes, many manufacturers offer customization options for floor drains. You can choose from various grate styles, shapes, and finishes to match your design preferences and architectural aesthetics.

8. Are stainless steel floor drains better than plastic ones?

Stainless steel floor drains are generally considered more durable, corrosion-resistant, and suitable for heavy-duty applications. However, plastic floor drains may be ideal for lighter-duty applications or budget constraints. The choice depends on the specific requirements of your project.

9. How long do floor drains typically last?

The lifespan of a floor drain depends on factors like material quality, usage, maintenance, and environmental conditions. Well-maintained floor drains made from high-quality materials can last many years or even decades.

10. Can I install or replace a floor drain myself?

While some DIY enthusiasts may be able to handle simple installations or replacements, it is generally recommended to hire a professional plumber for proper installation or replacement. They have the expertise, tools, and knowledge to ensure a successful and code-compliant installation.

Remember, specific questions or concerns about floor drains should be addressed to reputable manufacturers or professional plumbers who can provide tailored advice and guidance based on your unique requirements.

How to Select the Right Floor Drain Manufacturer: A Step-by-Step Guide?

Choosing the right floor drain manufacturer ensures you receive high-quality products, reliable customer service, and a seamless experience. Here is a step-by-step guide to help you select the ideal floor drain manufacturer:

1. Define Your Requirements:

Assess your specific project requirements, including the type of floor drain needed, size, materials, and customization options. Determine the quantity of floor drains you require and the budget you have allocated.

2. Research and Shortlist Manufacturers:

Conduct thorough research and identify reputable floor drain manufacturers. Look for manufacturers with a proven track record, positive customer reviews, and industry certifications. Consider their experience, product range, customization capabilities, and quality standards.

3. Evaluate Product Quality:

Examine the quality of the manufacturer’s products. Look for floor drains made from durable materials such as stainless steel or brass. Assess their floor drains’ strength, corrosion resistance, and overall construction: request samples or references to physically evaluate the quality if possible.

4. Consider Customization Options:

If customization is essential for your project, ensure the manufacturer can customize floor drains to your specifications. Inquire about their customization process, available options, and any additional costs involved.

5. Review Manufacturing Capabilities:

Assess the manufacturer’s manufacturing capabilities and facilities. Look for advanced equipment, technology, and processes that ensure precise manufacturing, reliable quality control, and efficient production. This helps ensure consistency and timely delivery of your floor drains.

6. Check Compliance with Standards:

Ensure that the manufacturer complies with relevant industry standards and certifications. Look for certifications such as ISO 9001, which indicate adherence to established quality management systems. Compliance with standards ensures the manufacturer’s commitment to producing reliable, high-quality floor drains.

7. Evaluate Customer Service and Support:

Assess the manufacturer’s level of customer service and support. Look for a responsive, communicative manufacturer that provides knowledgeable assistance throughout the purchasing process. Inquire about their after-sales support, warranty policies, and any technical assistance they offer.

8. Consider Pricing and Value:

Evaluate the pricing of the manufacturer’s floor drains and compare it to the value they provide. Consider the quality, customization options, customer service, and overall reputation of the manufacturer. Choose a manufacturer that offers a balance of competitive pricing and high value.

9. Seek Recommendations and References:

Contact industry professionals, contractors, or peers with experience working with floor drain manufacturers. Seek recommendations and references to gain insights into their experiences and satisfaction with specific manufacturers.

10. Request Quotes and Finalize the Selection:

Request detailed quotes from the shortlisted manufacturers that align with your project requirements. Evaluate the quotes, considering factors such as pricing, delivery timelines, and terms of service. Select the floor drain manufacturer that best meets your needs based on all the gathered information.

Following this step-by-step guide, conducting thorough research, and considering all relevant factors, you can select a reputable and reliable floor drain manufacturer like HOFEN Drain. This ensures you receive high-quality products, excellent customer service, and a successful partnership for your floor drain needs.