What’s the surface treatment?

Surface treatment intentionally creates an odd layer on the base, which stands out in mechanical, physical, and chemical properties different from the base material.

The overall working performance of the Bathtub drain is closely related to its surface property, and the surface performance cannot be achieved merely by the base material; thereby, surface treatment technology is needed to make the drain more resistant to corrosion and wear.

Overall, surface treatment for the Bathtub drain is to improve appearance, enhance texture, optimize function, etc.

For the metal base, commonly used surface treatment methods are

- Electrophoresis,

- Acid pickling,

- Wire drawing,

- Powder coating,

- Vacuum Plating,

- electroplating,

- Sand Blasting

Electrophoresis surface treatment for bathtub drain

Electrophoresis is a process that can coat the surface of stainless steel or aluminum alloy with a thin layer of insoluble material. Under an electric field, charged particles are attracted to opposite electrodes and deposited on the surface of the workpiece. This process can be used to create a variety of colors and finishes on the metal surface.

This finish is often used on bathtub drains because it is durable and corrosion-resistant. The electrophoresis process creates a smooth, uniform surface that is easy to clean and maintain. In addition, this finish is available in a wide range of colors, allowing you to choose a drain that matches your bathroom décor.

Electrophoresis may be the perfect option if you want a durable and attractive way to finish your bathtub drain. This cost-effective process can help create a unique look for your bathroom that will last years.

Advantages

The advantages of electrophoresis surface treatment of bathtub drains are as follows:

- It can form a smooth, bright surface with excellent corrosion, wear, and heat resistance.

- The electrophoretic paint has good adhesion to the substrate, and the coating has excellent toughness and flexibility, protecting the bathtub drain from external damage.

- This surface treatment can be used to coat a variety of metals, including aluminum, stainless steel, and brass.

- The electrophoretic paint is available in many colors, allowing you to choose a drain that matches your bathroom décor.

Acid Pickling surface treatment for bathtub drain

Acid pickling uses an acid solution to remove oxides and rust from the surface of a base material, such as steel. The oxide reacts with the acid to form salts dissolved in the acid solution. This makes it an excellent treatment for preventing rust. It can also be used as a pre-or intermediate treatment in processes such as electroplating.

Acid pickling is typically done using hydrochloric or sulfuric acid, although other acids can be used. The concentration of the acid solution and the treatment time will vary depending on the type of metal being treated.

Acid pickling is an effective way to remove rust and oxides from metal surfaces. Additionally, it can be used as a pretreatment in procedures like electroplating.

Advantages of bath tube drain with acid pickling surface treatment

The benefits of acid pickling surface treatment for bathtub drains are as follows:

- It can remove rust and oxides from the surface of the metal.

- In procedures like electroplating, it can also be employed as a pretreatment.

- The acid pickling solution is typically less expensive than other surface treatment options.

- Acid pickling is a relatively simple process that can be performed by trained personnel.

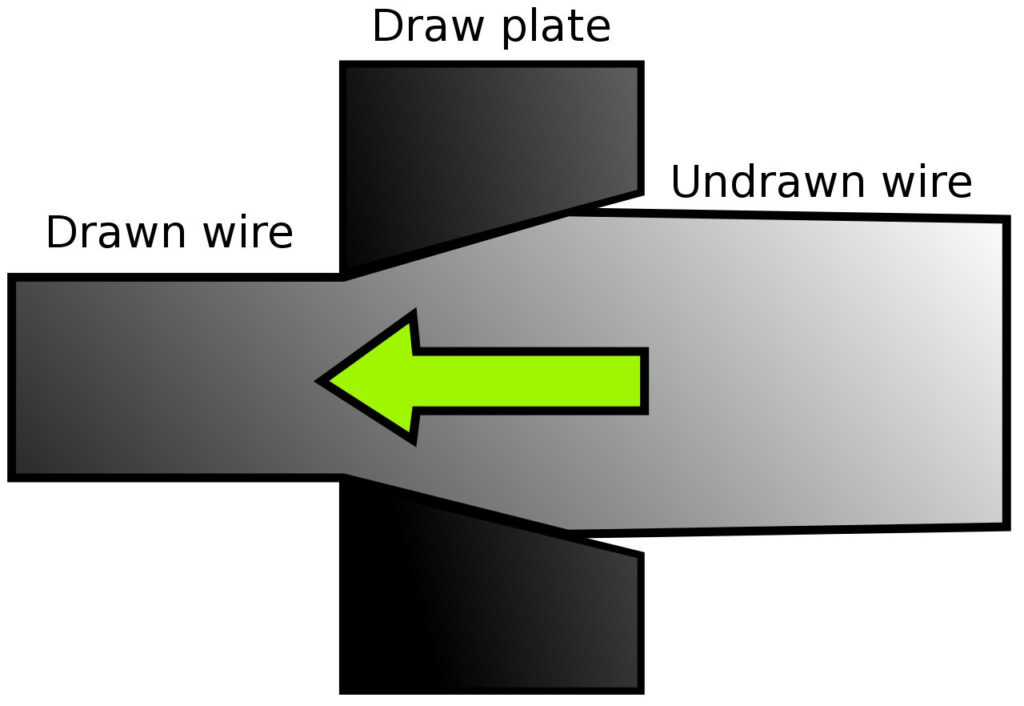

Wire Drawing surface treatment for bathtub drain

Wire drawing is a surface treatment for bathtub drains that creates a textured, matte finish. This finish is achieved by pulling a wire brush or other abrasive tool over the surface of the metal. The wire brush removes a small amount of metal, revealing a new layer of metal below. This new layer is typically darker in color and has a rougher texture than the surrounding metal. The wire drawing process can be repeated multiple times for a more pronounced effect.

Wire drawing is an effective way to create a unique, stylish look for your bathtub drain. This surface treatment can also help to hide scratches and other imperfections. In addition, wire drawing is a relatively simple and inexpensive process. Wire drawing may be the perfect solution to add personality to your bathroom.

Advantages of Wire Drawing surface treatment for bathtub drain

The benefits of wire drawing surface treatment for bathtub drain is as follows:

- It can create a unique, stylish look for your bathtub drain.

- This surface treatment can also help to hide scratches and other imperfections.

- Wire drawing is a relatively simple and inexpensive process.

Powder Coating surface treatment for bathtub drain

Powder coating for bathtub drains takes advantage of the electric discharge phenomena of the corona to make plastic powder adsorb on the metal workpiece. As a result of corona discharge, a dense charge is generated in its vicinity. This dense charge accelerates the movement of electrons and causes them to collide with gas molecules, resulting in the ionization of gas molecules. The ions produced are attracted to the workpiece and form a conducting path between the electrode and the workpiece. When the voltage is applied to the workpiece, an electric field is generated around the workpiece, which causes the powder particles to be attracted to the workpiece. The powder particles are deposited on the surface of the workpiece and form a uniform coating. A powder-coating surface treatment can enhance the bathtub drain’s longevity and attractiveness.

Powder coating is a method of applying plastic powder to a metal surface using an electric charge. The powder is then baked to create a solid surface. Compared to typical wet painting, powder coating provides benefits, including excellent color retention, enhanced resistance to wear and tear, and improved longevity. Powder-coating with proper procedures can also offer excellent corrosion resistance and environmental durability.

Advantages of Powder Coating surface treatment for bathtub drain

The benefits of powder coating surface treatment for bathtub drains are as follows:

- It can improve the appearance and durability of the bathtub drain.

- Several benefits of powder coating versus wet painting include excellent color retention, enhanced resistance to wear and tear, and improved longevity.

- Powder-coating with proper procedures can also offer excellent corrosion resistance and environmental durability.

Vacuum Plating surface treatment for bathtub drain

Vacuum Plating surface treatment for bathtub drains is a process that realizes the transfer of substances through physical reaction. Its function enables the base material to obtain better properties, including high strength, wear resistance, heat dissipation, corrosion resistance, etc. In addition, PVD can make various colors, such as gun color, gray, and champagne. Due to the complicated process, PVD relies heavily on manual operation.

The PVD process starts with cleaning the bathtub drain’s surface. To obtain good adhesion of the coating on the surface of the substrate during sputtering, it is necessary to perform a degreasing process on the surface of the substrate to remove oil and grease. The next step is to sputter a vacuum in an inert gas atmosphere. After deposition, PVD can provide a bright and lustrous finish resistant to tarnishing and corrosion.

Vacuum plating is an environmentally friendly surface treatment technology that does not produce wastewater or pollution during operation. Therefore, it is widely used in various fields, such as hardware products, watches, glasses, molds, etc. As science and technology advance constantly and people’s aesthetic needs, the application of PVD technology will become more widespread.

Advantages of Vacuum Plating surface treatment for bathtub drain

The benefits of vacuum plating surface treatment for bathtub drain is as follows:

- It can enable the base material to obtain better properties, including high strength, wear resistance, heat dissipation, corrosion resistance, etc.

- PVD can make various colors, such as gun color, gray, and champagne.

- Vacuum plating is an environmentally friendly surface treatment technology that does not produce wastewater or pollution during operation.

Electroplating surface treatment for bathtub drain

The most common surface treatment process is electroplating, which uses electrolysis to deposit metal or alloy on the surface of the workpiece, forming a uniform and dense metal layer.

This surface treatment attaches a metal film to the metal surface to improve its corrosion resistance and wear resistance while at the same time giving it a high glossy finish.

Under normal circumstances, electroplating does not require a heat source, and various coatings can be performed at an average temperature of 15-40°C.

The plating layer and the base material form an alloy that significantly enhances the product’s strength.

This process often protects surfaces from corrosion or wear and tear, such as on bathtub drains.

An electroplated coating on a bathtub drain will significantly extend its lifespan by protecting it from corrosion and everyday wear and tear.

This will not only save you money in the long term, but it will also save time and work because you won’t need to repair your drain as frequently.

Therefore, consider electroplating if you’re seeking a strategy to extend the life of your bathtub drain.

Advantages of Electroplating surface treatment for bathtub drain

The benefits of electroplating surface treatment for bathtub drain is as follows:

- It can protect surfaces, such as bathtub drains, from corrosion or wear and tear.

- An electroplated coating on a bathtub drain will significantly extend its lifespan by protecting it from corrosion and everyday wear and tear.

- This process often protects surfaces, such as bathtub drains, from corrosion or wear and tear.

- Electroplating can give the product a high-glossy finish. The plating layer and the base material form an alloy that significantly enhances the product’s strength.

Sand Blasting surface treatment for bathtub drain

Sandblasting is when sand or other materials are sprayed onto a surface at high speeds using compressed air. This method is frequently used to prepare surfaces for painting or other treatments since it may clean, smooth, or roughen a surface.

Sandblasting is a helpful technique for cleaning bathtub drains of corrosion, paint, and other debris. It may also be used to etch beautiful designs onto metal surfaces.

When sandblasting bathtub drains, it is vital to use the correct type of abrasive material and to control the speed and pressure of the stream of sand to avoid damaging the surface. With proper care, sandblasting can effectively improve the appearance and function of your bathtub drain.

Advantages of Sand Blasting surface treatment for bathtub drain

The benefits of sandblasting surface treatment for bathtub drain is as follows:

- It can clean, smooth, or roughen a surface.

- Sandblasting can remove rust, paint, and other materials from bathtub drains.

- The bathtub drain may be cleaned of rust, paint, and other debris with sandblasting, which can also be used to etch ornamental designs onto metal surfaces.

- It can also be used to create decorative patterns on metal surfaces.

- Sandblasting is an effective way to improve the appearance and function of your bathtub drain.